Mafura a sebelisoa liindastering tse pharalletseng joalo ka indasteri ea likoloi, lik'hemik'hale, kaho, masela, meaho, temo, merafo le ho cheka oli bakeng sa ts'ebetso ea bona e ntlehali ea ho se mamelle, mafura le ho hanyetsa kutu. Matšoenyeho a ho phalla joalo ka viscosity e phahameng haholo kapa e tlase haholo e ka khutsufatsa bophelo ba sesebelisoa le ho eketsa litšenyehelo tsa tlhokomelo. Ikakhetse ka setotsoana lintlha tse ling ka Lonnmeter fumana litharollo tse nepahetseng bakeng sa tekanyo e nepahetseng e tsoelang pele ea viscosity ho motsoako oa oli oa lube kapa mohala oa ts'ebetso ea tlhahiso. Latela mokhoa oa mokhoa oa boiketsetso oa indasteri.

Viscosity Index (VI) ea Setlolo ke Eng?

Viscosity Index (VI) ke tekanyo ea bohlokoa e hlalosang bokhoni ba lubricant ho boloka viscosity e tsitsitseng ho pholletsa le mefuta e mengata ea mocheso, thepa ea bohlokoa bakeng sa ho netefatsa ts'ebetso e tšepahalang maemong a fapaneng a ts'ebetso. VI e phahameng e bonts'a phetoho e nyane ea viscosity le ho feto-fetoha ha mocheso, e leng se etsang hore e be se loketseng bakeng sa lits'ebetso tse kang li-hydraulic system kapa lienjine tse pepesehileng maemo a leholimo a feteletseng. Ka lehlakoreng le leng, lubricant ea VI e tlase e na le liphetoho tse kholo tsa viscosity, tse ka senyang ts'ebetso. Mohlala, oli e tloaelehileng ea liminerale hangata e na le VI ea 95-100, athe oli e hloekisitsoeng haholo ea liminerale e fihla ho 120, 'me oli ea maiketsetso e ka fihlela li-VI tse fetang 250.

Melemo ea 'Maraka le Likopo tsa Indasteri

Mefuta eohle ea mafura e lokela ho fana ka ts'ebetso e ts'oanang le tlas'a maemo a feteletseng. Ts'ebetso ea tlhahiso ea mafura e tlas'a khatello e ntseng e eketseha ea ho fihlela litekanyetso tse thata tsa boleng, e susumetsoang ke tlhokahalo e ntseng e eketseha ea lihlahisoa tse khethehileng le linako tse khuts'oane tsa ho fana.

Mokhoa oa ho kopanya oli ea lubricant le mokhoa oa ho etsa oli ea lubricant o itšetlehile haholo ka taolo e nepahetseng ea sekhahla sa oli ea lubricant le viscosity ho netefatsa ts'epahalo ea sehlahisoa. Lisebelisoa tse phahameng tsa viscosity li sebetsa hantle haholo lits'ebetsong tse boima, ha litlolo tse nang le viscosity tse tlase li etselitsoe litsamaiso tsa lebelo le phahameng, tse nang le meroalo e tlase. E tsoetseng peleoli ea viscosity metres ea olithusa bahlahisi ho fihlela litlhoko tsena tse fapaneng ha ba ntse ba netefatsa ts'ebetso e nepahetseng, litšila tse fokotsehileng, le ho latela litekanyetso.

Index ea Viscosity ea Lubricant e khethiloe Joang?

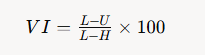

Ho khetholla Index ea Viscosity ho kenyelletsa mokhoa o tloaelehileng. Foromo ea lipalo tsa VI ke:

Moo:

- U ke viscosity ea lubricant ka 40°C.

- L ke viscosity ho 40 ° C ea oli ea litšupiso e nang le VI = 0, e ts'oanang le viscosity ea lubricant ho 100 ° C.

- H ke viscosity ho 40 ° C ea oli ea litšupiso e nang le VI = 100, e ts'oanang le viscosity ea lubricant ho 100 ° C.

Bakeng sa oli e phahameng ea viscosity (kinematic viscosity ho 100 ° C> 70 cSt), mokhoa o fetotsoeng oa logarithmic o sebelisoa ho netefatsa ho nepahala. Mokhoa ona o lumella bahlahisi ho lekanya botsitso ba mocheso oa lubricant, ho netefatsa hore e fihlela litlhoko tse khethehileng tsa ts'ebetso ts'ebetsong ea ho kopanya lubricant.

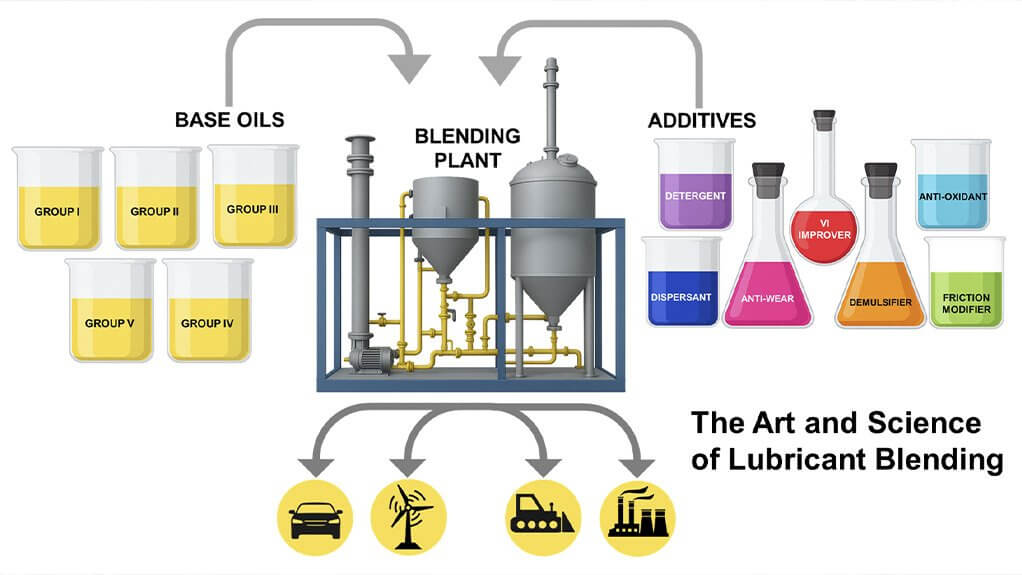

Mokhoa oa ho Kopanya Oli ea Lube & Mokhoa oa Tlhahiso

Ho kopanya oli ea setlolo ke mokhoa o rarahaneng oa khetho ea thepa e tala, ho kopanya, le taolo ea boleng. Lioli tsa motheo - liminerale, synthetic, kapa semi-synthetic - li tsoa ho tlhoekiso ea oli e tala ka vacuum distillation, ho ntšoa ha solvent, le hydrofinishing ho fihlela thepa e lakatsehang joalo ka viscosity, viscosity index, le ntlha ea ho tšela. Lioli tsena tsa motheo li kopantsoe le li-additives, tse kang li-index tsa viscosity index, li-anti-wear agents, li-detergents le li-antioxidants, ho ntlafatsa litšobotsi tsa ts'ebetso tse kang botsitso ba mocheso le ho hanyetsa kutu. Mokhoa oa ho etsa lubricant o kenyelletsa:

- Khetho ea Oli ea Base: Ho khetha oli ea liminerale kapa ea maiketsetso ho latela litlhoko tsa kopo.

- Khokahano e Kenyellelitsoeng: Ho kenyelletsa li-additives joalo ka li-viscosity modifiers ho tlhophiso ea thepa.

- Blending: Ho kopanya maemong a laoloang ho sebelisoa litanka tse kholo tse nang le li-stirrers ho netefatsa homogeneity.

- Taolo ea Boleng: Teko ea viscosity, density, flash point, le liparamente tse ling ho fihlela maemo.

- Packaging le Distribution: Ho kenya libotlolo kapa barreling bakeng sa phano ea 'maraka.

Ts'ebetso ena e hlokolosi e netefatsa hore mafura a sebetsa ka mokhoa o ts'epahalang lits'ebetsong ho tloha ho lienjine tsa makoloi ho isa mecheng ea indasteri, ka bongata ba oli ea lube le viscosity e sebetsang e le matšoao a bohlokoa a boleng.

High Viscosity vs. Low Viscosity Lubricating Oli

Khetho pakeng tsa oli e tlotsang ea viscosity e phahameng le oli e tlotsang ea viscosity e tlase e ipapisitse le litlhoko tsa ts'ebetso ea kopo. Litlolo tse phahameng tsa viscosity li loketse lits'ebetso tsa mosebetsi o boima, joalo ka oli ea gear kapa mafura a sebelisoang lisebelisoa tsa kaho kapa li-bearings tsa indasteri ea tšepe, moo li:

- Theha filimi e sireletsang e matla ho fokotsa likhohlano le ho apara tlas'a meroalo e phahameng.

- Ntlafatsa bokhoni ba ho jara, ho tšehetsa mechini e boima.

- Litšila tsa maraba tse kang litšila kapa lithōle tsa tšepe, ho thibela tšenyo e ka holimo.

- Boloka botsitso mochesong o phahameng, ho netefatsa ts'ebetso e tšepahalang.

Leha ho le joalo, mafura a viscous haholo a ka eketsa tšebeliso ea matla le lisebelisoa tsa khatello. Ka lehlakoreng le leng, litlolo tse nang le viscosity tse tlase li lumellana le lits'ebetso tsa lebelo le phahameng, tse boima bo tlase joalo ka lienjineri tsa likoloi kapa li-hydraulic system, tse fanang ka:

- Phallo e ntlafalitsoeng bakeng sa ho potoloha hantle le ts'ebetso e batang ea ho qala.

- Ho fokotseha ha tšebeliso ea matla ka lebaka la khohlano e tlase ea kahare.

- Phallo e matlafalitsoeng ea mocheso lits'ebetsong tsa lebelo le phahameng.

Leha ho le joalo, oli e tlaase ea viscosity e ka 'na ea hlōleha ho fana ka tšireletso e lekaneng tlas'a meroalo e phahameng, e lebisang ho apara.

Ho se sebetse hantle

Ho Sekisetsa ho Defoaming le Demulsibility: Ho lebisa ho se sebetseng hantle.

Keketseho ea Khohlano le Mocheso

Botenya bo feteletseng bo sitisa phallo, ho potlakisa oxidation le ho etsa varnish kapa sludge.

Likotsi tse Bakiloeng ke Viscosity e Phahameng haholo kapa e Tlaase Haholo

Viscosity e fosahetseng ea mafura e ka lebisa mathateng a bohlokoa a ts'ebetso, litaba tsa seipone tse bonoang lits'ebetsong tse kang ts'ebetso ea ho belisoa ha penicillin moo taolo e nepahetseng e leng bohlokoa. Oli e tlotsang ea viscosity e phahameng e baka likotsi tse kang:

- Tšebeliso e Phahameng ea Matla: Ho hlokahala matla a mangata ho hlōla khanyetso, ho eketsa litšenyehelo.

- Ts'ebetso e Fosahetseng ea Cold-Start: Phokotso e fokotsehileng ea kotsi ea lisebelisoa tse senyehang ka mocheso o tlase.

Ka lehlakoreng le leng, oli e tlotsang ea viscosity e tlase e ka fella ka:

- Tlhahiso e sa Lekaneng ea Lifilimi: Tšireletso e sa lekaneng ea holim'a metsi e eketsa moaparo le ho hloleha ha likarolo.

- Boikutlo bo Eketsehileng ba Tšilafalo: Lioli tse tšesaane ha li sebetse hantle ho ts'oara maloanlahla.

- Keketseho ea Khohlano le Mocheso: E khothaletsa oxidation le ho fokotsa nako ea bophelo ea lubricant.

Likotsi tsena li totobatsa tlhoko ea taolo e nepahetseng ea ts'ebetso ea ho kopanya oli ea lubricant ho sebelisoa tlhahlobo ea viscosity ea nako ea nnete ho netefatsa ts'ebetso e ts'oanang.

Boleng ba Viscosity Measurement ho Automation Process Line

Ho kenyelletsa tekanyo ea viscosity ea nako ea 'nete ha ho kopanngoa le melapo ea othomathike ho fetola ts'ebetso ea tlhahiso ea lubricant, e fanang ka:

- Precision Blending: E netefatsa homogeneity, e thibela li-batch tse sa khetheheng le ho kopanya hape ho theko e boima.

- Katleho ea Litšenyehelo: E fokotsa tšebeliso ea matla, tlhahiso ea oli e thellang, le ho kenella ka letsoho.

- Netefatso ea Boleng: E boloka ho latela maemo a kang ASTM D445, ho netefatsa kamohelo ea 'maraka.

- Ntlafatso ea Ts'ebetso: E fokotsa linako tsa ho kopanya ha o ntse o fumana thepa e tšoanang.

- Scalability: E tšehetsa liphetoho tse se nang moeli ho tloha ho sefofane ho ea ho tlhahiso e feletseng.

- Tlhahlobo e Tsoelang Pele ea Taba: E hloaea liphoso tsa tšilafalo kapa tsa ho kopanya hang-hang, e fokotsa nako.

Ka ho iketsetsa taolo ea viscosity, bahlahisi ba fihlela tlhahiso e nakong, ba ntlafatsa maemo, 'me ba fihlela litlhoko tsa mmaraka oa tlholisano, ho latela ho nepahala ho hlokahalang ho belisoa ho tsoelang pele ha penicillin.

Mathata a Tloaelo ea Ts'ebetso ea Setso

Tlhokomelo ea tloaelo ea ho kopanya mafura e itšetlehile haholo ka lisampole tse sa sebetseng le liteko tse thehiloeng lab, joalo ka Saybolt Universal Viscometer, e hlahisang liphephetso tse kholo:

- Ho lieha ha nako: lisampole le tlhahlobo ea lab li hlahisa li-lags, li sitisa liphetoho tsa nako ea nnete.

- Ho se nepahale: Liphetoho tsa mocheso le ho kuta nakong ea sampole li senya ts'epahalo ea data.

- Matla a Mosebetsi: Sampling ea letsoho e eketsa litšenyehelo tsa ts'ebetso le likotsi tsa liphoso tsa batho.

- Likotsi tsa Tšilafalo: Mekhoa e sa lumellaneng ea lisampole e ka hlahisa liphoso kapa tšilafalo e fapaneng.

- Scalability e Lekanyelitsoeng: Mekhoa ea kantle ho Marang-rang e thatafalloa ho tsamaisana le litlhoko tse phahameng tsa tlhahiso.

Meeli ena e etsa hore mekhoa ea setso e seke ea tšoanela limela tsa sejoale-joale tse kopanyang oli, moo lebelo, ho nepahala le boiketsetso li leng bohlokoa bakeng sa ho boloka tlholisano.

Bohlokoa ba Tekanyo ea Nako ea Sebele ho Kopantsoeng

Tekanyo ea viscosity ea nako ea 'nete e fetola mokhoa oa ho kopanya lubricant ka ho fana ka data e potlakileng, e nepahetseng e tsamaisang katleho le boleng. Melemo ea bohlokoa e kenyelletsa:

- Ho Felisoa ha Reblending: Ho beha leihlo khafetsa ho netefatsa ho kopana ho itseng, ho fokotsa litšila le litšenyehelo tsa matla.

- Mehato e Fokotsoeng ea Manual: Automation e fokotsa ho kenya letsoho ha opareitara, e fokotsa litšenyehelo le liphoso.

- Nako e Loketsoeng ea ho Kopanya: Litokiso tsa nako ea 'nete li thibela ho tsoakana ho feta tekano kapa ka tlase, ho boloka nako le lisebelisoa.

- Ts'ebetso ea Ts'ebetso: Tlhahlobo ea onsite e fokotsa tlhoko ea tlhahlobo ea lab ntle le sebaka, ho fokotsa litšenyehelo tsa ho tsamaisa thepa.

- Melemo ea Tikoloho: E eketsa tšebeliso ea oli, e fokotsa litšila le tšusumetso ea tikoloho.

- Tlhahlobo e Ntlafetseng: E latela liphetoho tsa boemo ba oli, e nolofalletsang ho lemoha tšilafalo kapa ho senyeha kapele.

Tharollo ea Sehlahisoa sa Lonnmeter: Lube Oil Viscosity Meter

Li-viscosity metres tsa oli tsa Lonnmeter li entsoe ho fihlela litlhoko tse matla tsa ts'ebetso ea tlhahiso ea oli ea lubricant, e fana ka litharollo tsa morao-rao tsa tlhahlobo ea nako ea nnete. Lintlha tsa bohlokoa li kenyelletsa:

- Wide Viscosity Range: Mehato ea 10-10,000,000 cP, e amohelang metsoako e rarahaneng.

- Boitshoko ba Mocheso o Phahameng: E sebetsa ho fihla ho 350°C, e loketse ditikoloho tsa ho kuta haholo.

- Tlhokomelo e Kopantsoeng ea Mocheso: E sebelisa li-viscosity meter ea oli e nepahetseng haholo bakeng sa lipalo tse nepahetseng tsa viscosity tse lefelloang ka mocheso.

- Seamless Automation: E kopanya le litsamaiso tsa PLC le DCS bakeng sa taolo e ikemetseng.

- Moralo o Matla: Li-sensor tse sa sebetseng, tse hlokang tlhokomelo tse se nang lisebelisoa, tse netefatsang ts'epahalo.

- Ho Reka Lintlha le Ts'ireletso: Ho boloka data ka boits'oaro ka likhoutu tsa nako, ho thibela liphetoho tse sa lumelloeng le ho nolofalletsa tlhahlobo ea maemo.

Limithara tsa Lonnmeter, tse ts'oanang le tsa Rheonics' SRV le SRD, li fana ka litekanyo tsa viscosity le density, e tlosa ho se nepahale ha mekhoa ea setso joalo ka Saybolt viscometer. Bokhoni ba bona ba ho sebetsana le maro a seng a Newtonian bo netefatsa boleng bo tsitsitseng ho kopantseng lubricant, ho tšehetsa likopo ho tloha ha ho etsoa ho fihlela tlhahiso ea ho qetela.

Taolo ea viscosity e nang le boiphihlelo e fana ka boleng bo ts'oanang, e fokotsa litšenyehelo, e ntlafatsa scalability, 'me e netefatsa ho latela litekanyetso tse kang ASTM D445. Ikopanye le Lonnmeter kajeno ho hlahloba litharollo tsa bona tsa morao-rao tsa tekanyo ea viscosity le ho fetola mokhoa oa hau oa tlhahiso!

Nako ea poso: Aug-14-2025