Tekanyo ea viscosity ea polymer e lekanya mokhoa oa extrusion le oa ho bopa. Tlhokomelo ea nako ea sebele ea viscosity e bohlokoa ho feta mocheso le khatello ea khatello.

Overviehof ExtrronanMoldingProcess

Extrusion molding ke mokhoa o atlehang oa ho etsa liindasteri tse ngata bakeng sa tlhahiso ea litlaleho tse tsoelang pele tse kang liphaephe, lifilimi, maqephe, joalo-joalo E nolofalletsa tlhahiso ea libopeho tse rarahaneng tsa likarolo tse fapaneng ka boleng bo tsitsitseng ha li ntse li tiisa lebelo le phahameng la tlhahiso le katleho ea thepa. Likhatelo-pele tse totobetseng tse kang mokhoa oa ho iketsetsa lintho, ho beha leihlo ka nako ea sebele le ho hlahloba ts'ebetso ea ts'ebetso hape li ntlafalitse ho nepahala le ho fokotsa tšusumetso ea tikoloho ka ho fokotsa litšila.

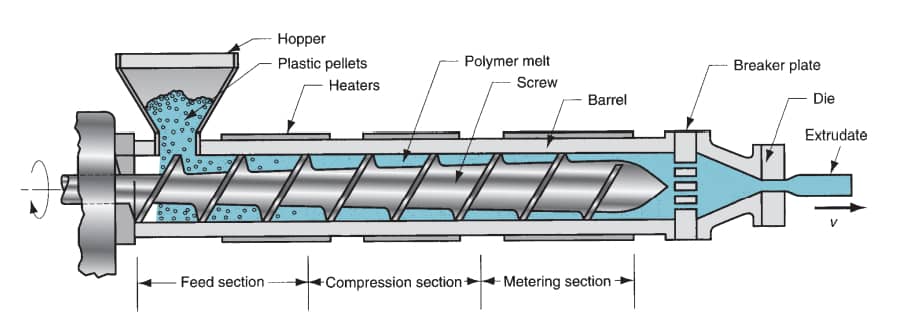

Rough IDEA eaExtrusihoMachine

Mochini oa extrusion o na le likarolo tse latelang: hopper, sekoti sa ho fepa, lisebelisoa tsa ho futhumatsa le pompo ea gear. Lintho tse bonahalang li kenngoa ka har'a mochine ka hopper. Sekurufu sa ho fepa se ntseng se bilika, se khannoang ke enjene le lebokose la gear, se tsamaisa thepa ka har'a moqomo le ka har'a dae. Lintho tse futhumatsang haufi le barrel li boloka mocheso o laoloang ho nolofatsa le ho qhibilihisa thepa ea polymer. Ka mor'a ho tsoa lefing, ntho e qhibilihisitsoeng e kena ka har'a hlobo e nang le lesoba le le leng kapa ho feta, moo e pholileng ebe e tiisa sebopeho se batlang. Litsamaisong tse ling, pompo ea gear e beoa lipakeng tsa moqomo ebe e shoa ho netefatsa khatello e tsitsitseng linthong tse tsoang.

Lintlha tsa bohlokoa tsa Tekanyo ea Viscosity mochining oa Extrusion

Hopper Exit / Feed Zone: E lekanya viscosity ea pele ea ho qhibiliha ha polima e qala ho nolofala.

Melting Zone (Mid-Barrel): E ts'oara phetoho ho boemo ba ho qhibiliha ka botlalo.

Sebaka sa Metering(Pele ho Gear Pump kapa Die): E lekanya tekanyo ea viscosity ea polymer tlas'a litekanyetso tsa ho kuta.

Monyako oa Lefu: E fana ka data ea nako ea sebele ea ho qhibiliha viscosity sebakeng sa extrusion.

Ho utloisisa Polymer Melt le Viscosity

Polymer melt ke eng?

Ke polymer e futhumetseng ho fihlela boemo bo qhibilihisitsoeng, e bonts'ang thepa ea phallo e lumellang ho bopa ka extrusion kapa ho bopa. Theqhibilihisa viscosity ea li-polymers-ho hanyetsa ho phalla-ho itšetlehile ka boima ba limolek'hule, mocheso, sekhahla sa ho kuta, le li-additives, tse susumetsang matla le qetello ea sehlahisoa sa ho qetela. Homokhoa oa polymer extrusion, moo polymer e entsoeng ka ho qhibilihisoa e fetisetsoang ka lesela, le ka ho etsoa ha ente, moo e tlatsang hlobo tlas'a khatello, e boloka e le hantle.qhibilihisa viscositye bohlokoa. Tloaelotekanyo ea viscosity ea polymer qhibilihamekhoa, joalo ka off-line capillary rheometry, hangata e lieha ka lebaka la tieho, e lebisang phetoho hoe mochengviscometer bakeng sa li-polymersbakeng sa temohisiso ea nako ea nnete.

Mathata ho Polymer Extrusion le Taolo ea Ts'ebetso

Themokhoa oa polymer extrusion'me ho etsa ente ho tobana le litšitiso tse kholo ho boloka botsitsoqhibilihisa viscosity. Phapang ka lebaka la likhahla tsa mocheso le ho feto-fetoha ha sekhahla sa ho kuta ho ka lebisa ho se leka-lekanengqhibilihisa viscosity ea li-polymers, e bakang likoli joalo ka bofokoli ba bokaholimo kapa li-voids ho profaele e kentsoeng. Mehala e meholo ea extrusion e loantšana le junifomotekanyo ea viscosity ea polymer qhibilihaho pholletsa le phallo, ho boloka ho lumellana le taolo ea ts'ebetso. Ha ho etsoa ente ka lebelo le phahameng, litokiso tsa matsoho li hloleha ho tsamaisana le linako tse potlakileng tsa potoloho, ho beha kotsi ea warpage kapa ho tlatsa ho sa fella. Liphephetso tsena li totobatsa tlhoko ea tsoelo-pelepolymer viscometerlitsamaiso, joalo kaviscometer ea polymer e ikemetseng, ho fana ka lintlha tsa nako ea sebele le ho hlōla mefokolo ea mekhoa ea setso.

Ke Hobane'ng ha Melt Viscosity Monitoring Matters

Tekanyo ea ho qhibiliha ea viscosity e bohlokoa ts'ebetsong ea polymer extrusion le ho bopa ente ka mabaka a 'maloa. Ho extrusion, viscosity e sa fetoheng ea ho qhibiliha e netefatsa hore lefu le tlala le ho thibela mefokolo joalo ka ho se lekane ha holim'a metsi kapa ho ruruha ha lefu. Ha ho etsoa ente, e ama ho tlatsoa ha hlobo, boleng ba karolo, le nako ea potoloho, moo ho fapana ho ka lebisang ho warpage kapa ho tlatsa ho sa fella. Tlhokomelo ea nako ea 'nete e lumella basebelisi ho fetola mocheso, khatello, kapa sebopeho sa thepa ho fofa, ho ntlafatsa ts'ebeliso ea matla le ho fokotsa litšila - mathata a bohlokoa ha melaoana ea khabone e ntse e tiisa ka 2025.

Ho rarahana ha tekanyo ea polymer melt viscosity ho hlaha ho tlhaho e seng ea Newtonian ea ho qhibiliha ha polymer, moo viscosity e fapaneng le sekhahla sa ho kuta le nalane ea mocheso. Sistimi ea inline polymer-melt viscometer system e sebetsana le sena ka ho fana ka data e tsoelang pele, e nolofalletsang taolo ea ts'ebetso eo mekhoa ea kantle ho naha e ke keng ea lumellana.

Tsebo ea Lonnmeter ho Melt Viscosity Monitoring

Ka lilemo tse fetang leshome tsa boiphihlelo,Lonnmeter, ea etellang pelemorekisi oa viscometer ea polymer, e iketselitse e le pula-maliboho hoho shebella viscosity. Boitseanape ba bona bo akaretsa likhatello tse phahameng, lithapo tse phahameng tsa mocheso le lisebelisoa tsa ho bopa ente, ho sebetsana le litlhoko tsa li-polymer tse fapaneng joalo ka polyethylene, polypropylene le PET.

Litharollo tsa Sehlahisoa

Lonnmeter e fana ka maemo a holimopolymer qhibiliha viscometerlitharollo tse etselitsoengqhibilihisa viscosity monitoring. TheInline Viscometere etselitsoe ho kenngoa ka perpendicular kapa parallel ka mechine ea extrusion, ho lekanyaqhibilihisa viscosityho fihlela ho 100,000 cP·s le mocheso o fihlang ho 300 ° C, o sa amehe ke mefuta e fapaneng ea phallo.

Ho itloaetsa ke lets'oao le ikhethileng la linyehelo tsa Lonnmeter, tse nang le likhetho tsa likhokahano tse khokahantsoeng kapa tse nang le marang-rang le tlhahiso ea data ka 4-20mA kapa RS485, e hokahaneng ntle le moroallo le litsamaiso tsa othomathike. Ka extrusion, setupo sa perpendicular se tiisa tšitiso e fokolang ea phallo.

Melemo ea Litharollo tsa Lonnmeter's Melt Viscosity

Netefaletso ea boleng:Hona joaletekanyo ea viscosity ea polymer qhibilihae netefatsa li-extrudates tse se nang sekoli le likarolo tse bōpiloeng.

Tšebeliso e Ntle ea Litšenyehelo:Ho fokotsa litšila le tlhokomelo ho theola litšenyehelo tsa ts'ebetso.

Ho Boloka Matla:Litokiso tse nepahetseng li ntlafatsa tšebeliso ea matla.

Mokhoa oa ho Fetoha:Ho lumellana le li-polymer tse fapaneng ho tšehetsa litlhoko tse fapaneng tsa tlhahiso.

Tšireletseho e Matlafalitsoeng:Ho lemoha kapele ha li-viscosity anomalies ho thibela khatello ea lisebelisoa.

FAQs

Hobaneng ha viscosity ea qhibiliha e le bohlokoa ho feta mocheso kapa khatello?

Melt viscosity e ama ka kotloloho phallo ea ho qhibiliha, ho tlatsa lefu, le ho tsitsa ha sehlahisoa, hangata ho feta tšusumetso ea mocheso kapa khatello. Tekanyo e nepahetseng ea polymer melt viscosity e thibela liphoso tse kang warpage kapa lefu la ho ruruha, e leng se etsang hore e be bohlokoa bakeng sa taolo ea ts'ebetso.

Lonnmeter e netefatsa joang kopanyo ea data?

Viscometer ea othomathike ea polymer e kopanya ka liprothokholo tsa 4-20mA kapa RS485, e fanang ka data ea nako ea nnete ho laola lits'ebetso. Rahistori oa eona o ka har'a sekepe, o fumaneha ka software, o fana ka lintlha tsa nalane, tse fetang meeli ea setso ea viscometer polymer.

Ke lintlha life tse susumetsang ho qhibiliha viscosity ea li-polymer?

The melt viscosity ea li-polymers e susumetsoa ke boima ba limolek'hule, mocheso, sekhahla sa ho kuta, le boteng ba li-additives kapa li-filler. Boima bo phahameng ba limolek'hule le mocheso o tlase hangata li eketsa viscosity, tse amang mokhoa oa polymer extrusion.

Melt viscosity monitoring ke lejoe la sekhutlo la tšebetso ea polymer extrusion le ho bopa ente, ho netefatsa boleng le ts'ebetso. Ka boiphihlelo bo netefalitsoeng ba Lonnmeter le viscometer e tsoetseng pele bakeng sa lipolima, bahlahisi ba ka hlola liphephetso taolong ea ts'ebetso le ho ntlafatsa tlhahiso. Kopa qotsulo kajeno ho morekisi enoa ea tšepahalang oa polymer viscometer!

Nako ea poso: Jul-31-2025